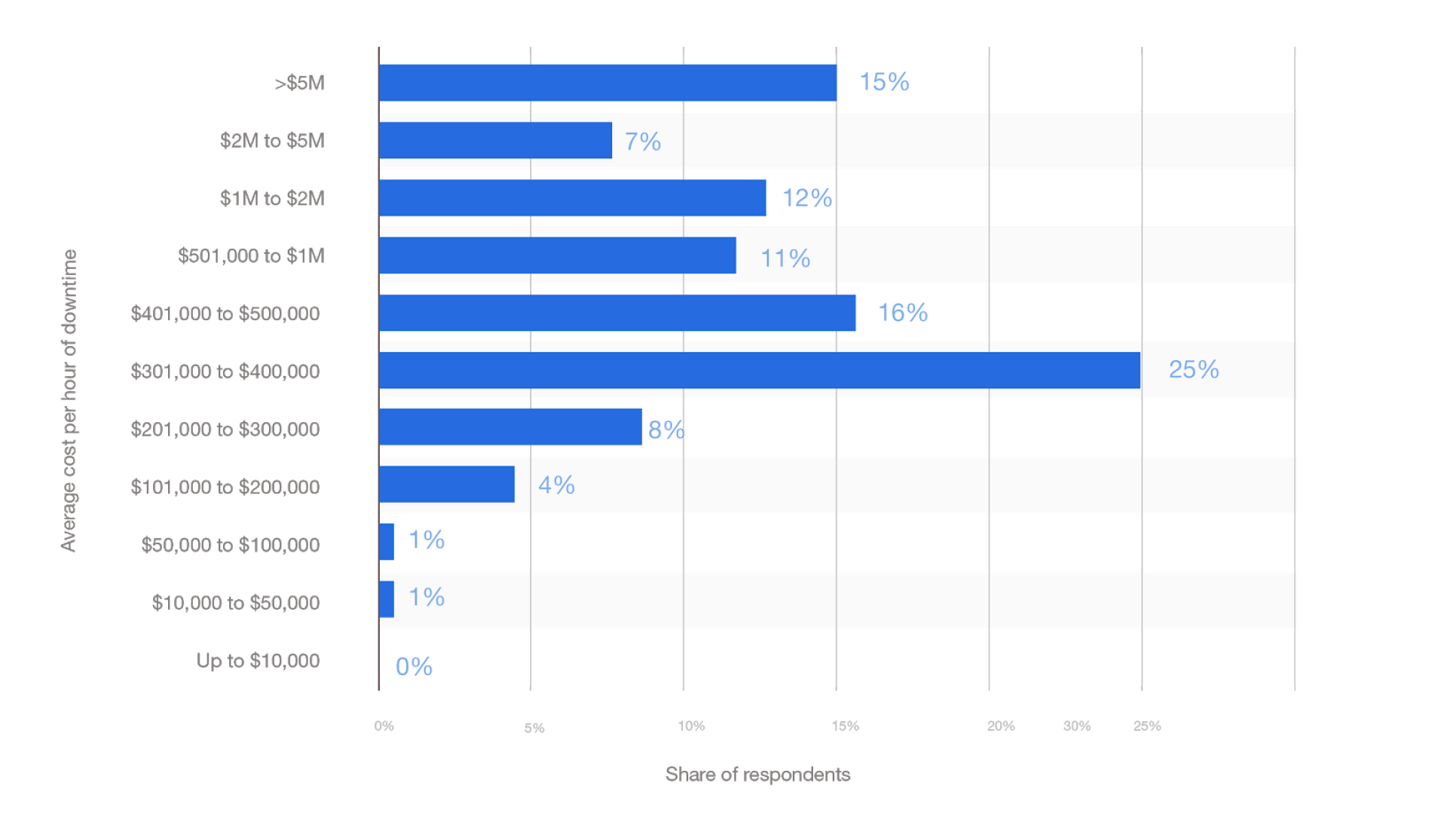

Unplanned maintenance and downtime can adversely impact the financial planning of any business. A quarter of surveyed organizations worldwide claimed that the average hourly downtime cost of their servers was between $301,000 and $400,000 in 2019.

The cost of downtime, however, does not only show up in dollar form. When machines are down, business and supply chain processes are paralyzed, human safety is at risk, and maintenance engineers –– instead of focusing on more value-adding tasks –– are pressured to put the operation back to normal as soon as possible. If they use a reactive approach to machine maintenance, chances are they will spend a lot of their precious time on figuring out the cause of downtime.

Many businesses have been practicing calendar-based and reactive maintenance approaches, using conventional metrics such as the age of the equipment. But age is just one of the many factors that influence machine performance, and most of them can be hard to detect and prevent. For example, cyber-attacks, design flaws, and human errors can cripple a machine at any moment.

Ensuring uptime can be harder to fulfill in a fast-growing Industry 4.0 environment. This is why you should enable a powerful mechanism that allows your organization to proactively detect and fix equipment failures and avoid the costly consequences of downtime.

Let your machine tell you they’re not OK — in real-time.

Supercharging your machines with the Internet of Things (IoT) can offer a lot of competitive advantages that conventional approaches to equipment maintenance cannot provide.

IoT enables Conditional Monitoring, which is a prerequisite to Predictive Maintenance. By leveraging IoT based predictive maintenance, you can significantly reduce costs. According to a McKinsey & Company report, IoT-enabled predictive maintenance could potentially save businesses $200 billion to $600 billion by 2025.

IoT makes machines smarter. It allows them to generate data about their performance and condition (e.g., machine temperature, pressure, and vibration) and share it in real-time with other machines or devices.

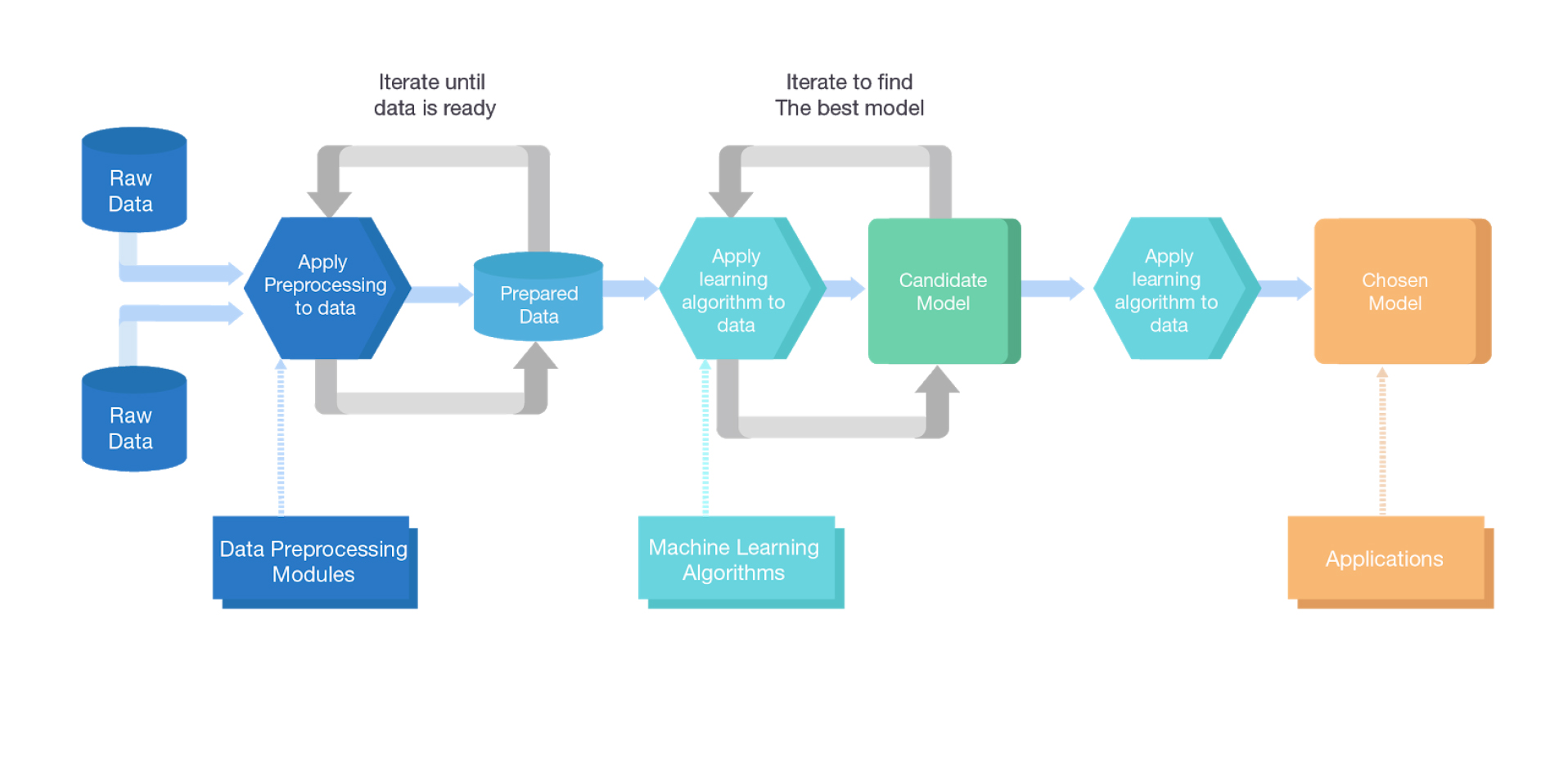

Collecting huge swathes of machine data, however, is just half the battle. Turning them into meaningful and actionable insights is also crucial. This is where Artificial Intelligence (AI) and Machine Learning (ML) comes in.

AI and ML allow you to turn raw machine data into predictive models for maximizing uptime. With established models, you can automatically detect an anomaly/damage and irregular behavior, get repair recommendations, and predict outcomes.

Like a human brain, “AI’s brain” has interconnected neurons (neural networks) that receive and process data. With sufficient amount of data and using Deep Learning (a machine learning method) and Big Data Analytics, AI can be trained to understand the patterns in the series of data it receives from the machine and determine if there is an unusual machine behavior or event (such as abnormal increase in energy consumption) that can lead to a failure or downtime

The combined power of IoT, AI, and ML allows you to intelligently predict machines’ remaining useful life (RUL), irregular behavior, and failure patterns and make proactive decisions and actions. It also helps you automate maintenance scheduling and implementation so you can minimize errors and costs.

Building resilient systems at scale, however, can be hard and tricky particularly if you lack the needed resources. Ensure that you have the right mix of talents, technologies, and best practices to intelligently build and manage a resilient network of smart machines.

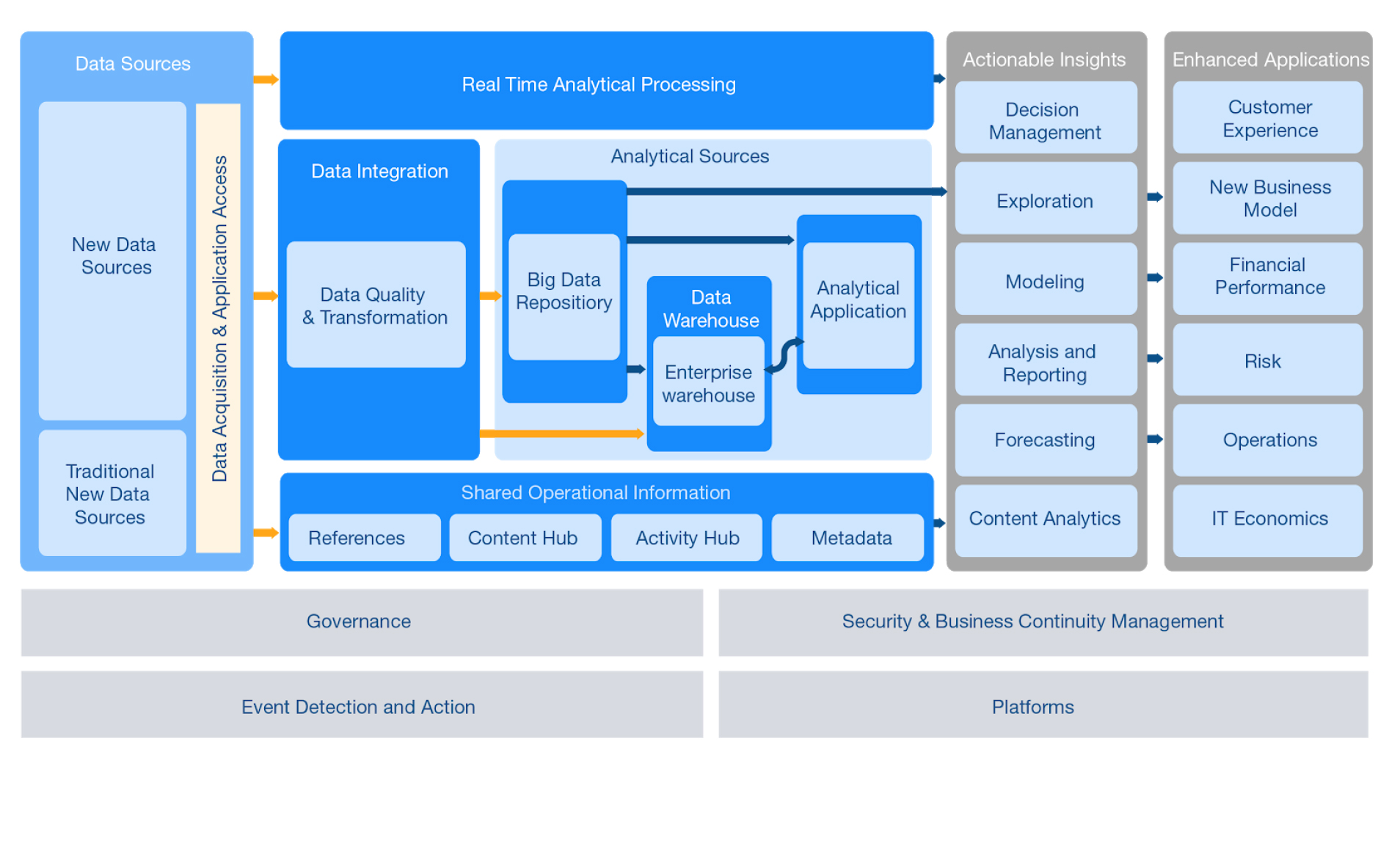

Leveraging its smart solutions, SmartIMS can help you more effectively integrate IoT, AI, and ML into your machines and critical infrastructures to ensure optimal equipment maintenance and uptime.

Our Data Science Laboratory provides you with advanced and comprehensive Machine Learning and Deep Learning capabilities including predictive maintenance, fraud detection, and time-series analysis. Our team of experts can assist you in assessing your current environment and determining how to best weave these solutions into your equipment; effectively make sense of smart data; automate insights to decision, and easily scale these capabilities as needed.

Contact us to learn more.